The Sheerline.

I have to confess the one aspect of the Norwalk Islands Sharpie that I struggle with is it’s sheer as it approaches the bow. It can appear to reverse the curve, or at least flatten out. This bothers me as I really dislike reversed sheers, and I adore simple, strong, and perky curves.

What is the sheer? It is the line on the edge of the boat, that when seen from the side of the boat, goes from the back to the front. It typically arcs from lower at the stern (back), to higher at the bow (front). It’s a practical idea, as a boat moves forward, it has to break through the water and waves, and a higher bow will protect the boat from taking on water.

It has to be considered that a sheer is rarely seen from just beam on (from the side), we see a finished boat from many directions as it moves past us. In the case of a sailing boat, we see it heeled (leaning) from both the windward (sheer up high) and leeward sides (sheer down by or in the water).

Since the outset, I’ve keenly wanted to have a perky sheer, even turning my nose up at some NIS builds with what I claim as reversing sheers. Well now the rubber is meeting the road, and as far as Troy and I can tell, we’re close to the plans. I can see this flattening and I have discovered what happens sheer of an NIS thanks to some long chat’s with Troy and careful observation…

The sheer climbs strongly from amidships but as it reaches the foredeck, it is less aggressive, but it is still climbing. What softens the sheer is the camber on the foredeck, an effect that is not easily seen. At the front of the cabin the side decking takes on a curve that as it progresses forward, creates a crowned foredeck, which is ideal for shedding water off the boat not just down the side decks aft.

So this crowned foredeck, when seen from the side, gets mixed in with the sheer line, flattening it, and the effect is further exaggerated when the boat is heeling (leaning over).

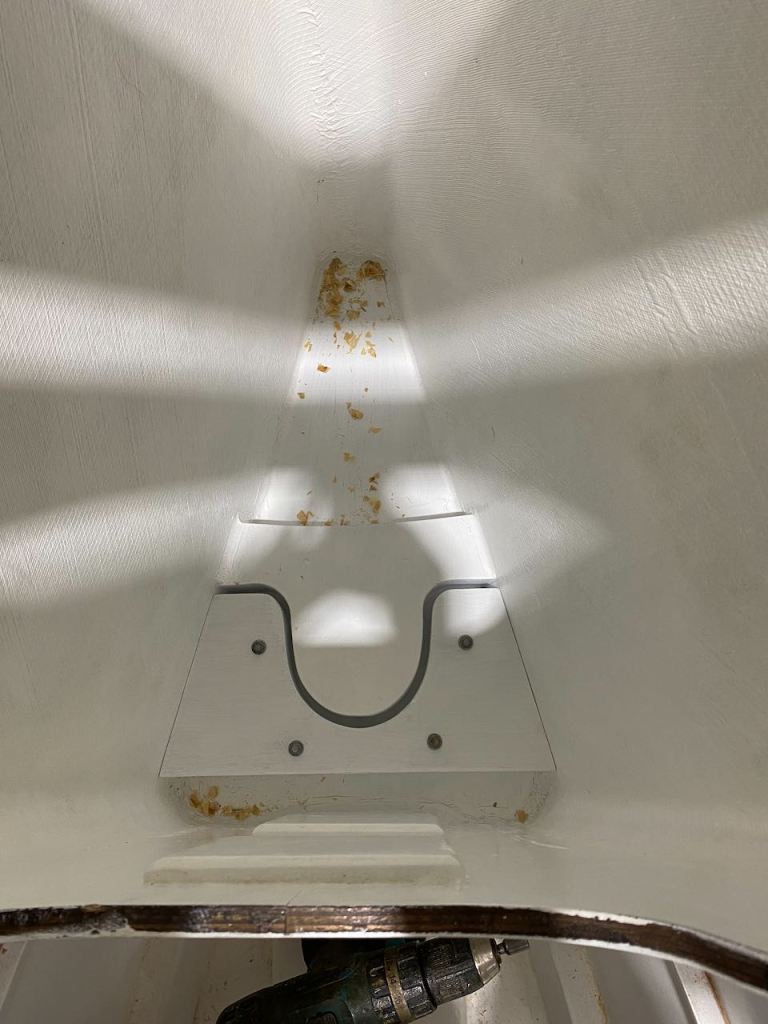

What to do about it…I plan to create a contrasting a sheer line with dark timber or paint, and design some fairleads (guides for ropes that pass over the bow), that follow the sheer line and rise up further exaggerating the sheer. This should all help keep eyes on what I want to be the sweetest of lines.

Or, I could be nuts.